Manufacturing

#1

Time Series Database

Source: DB Engines

1B+

Downloads of InfluxDB

See every signal. Act in real-time.

Machines on factory floors stream data constantly, often at sub-second resolution, relaying condition, performance, and yield metrics. InfluxDB ingests this IIoT data, or high-frequency time series, in real-time to spot anomalies, avoid downtime, and optimize operations.

Time series data shows the full picture—past, present, and next—powering predictive maintenance and true Industry 4.0 readiness.

Purpose-built for the scale and precision of modern manufacturing

Massive ingestion throughput

Ingest millions of unique data streams—from every machine, device, and sensor from PLCs, SCADA, and OT systems to monitor production lines, machine health, and supply-chain equipment.

Real-time analytics

Query millions of series in less than 10 ms to drive automated quality checks, trigger alerts, or feed ML models for adaptive process control.

Unified operational visibility

Create a single source of truth across plants, lines, and sites. Break down silos so operations, engineering, and IT teams can monitor, report, and perform root-cause analysis in real-time.

Edge-first, real-time processing

Run anomaly detection and predictive models at the edge—even with intermittent connectivity—for faster response where it matters most.

Real-time foundation for industrial scale

Global manufacturers count on InfluxDB to power mission-critical systems at scale. From heavy equipment to complex production lines, they depend on its proven reliability and security to meet strict uptime demands and expand analytics as connected assets grow.

Siemens Energy’s automated factory, which builds battery modules for marine vessels and electric ferries, uses InfluxDB to handle high-cardinality sensor data from production lines and customer sites. By capturing performance metrics and test results, InfluxDB helps ensure consistent battery quality and reliability.

Read announcement

PTC ThingWorx integrates with InfluxDB to collect high-frequency sensor data at the edge and analyze it in real time, cutting costs and speeding digital transformation while delivering instant operational insight across legacy and modern systems.

Read announcement

Everllence (formerly MAN Energy Solutions) runs its MAN CEON platform on InfluxDB Cloud to analyze billions of time-series readings from large-scale engines & equipment. By spotting issues early & guiding performance tuning, CEON helps manufacturers & industrial operators boost efficiency, cut fuel use, and drive toward lower-emission operations.

Read Announcement

Bosch Rexroth uses ctrlX AUTOMATION with InfluxDB to deliver real-time, edge-ready monitoring across factories. InfluxDB runs on ctrlX CORE devices and scales to plant and cloud, giving instant insight into machine health, energy use, and production trends. Manufacturers cut downtime, enable predictive maintenance, and drive continuous improvement with a flexible, data-driven foundation.

Watch webinar

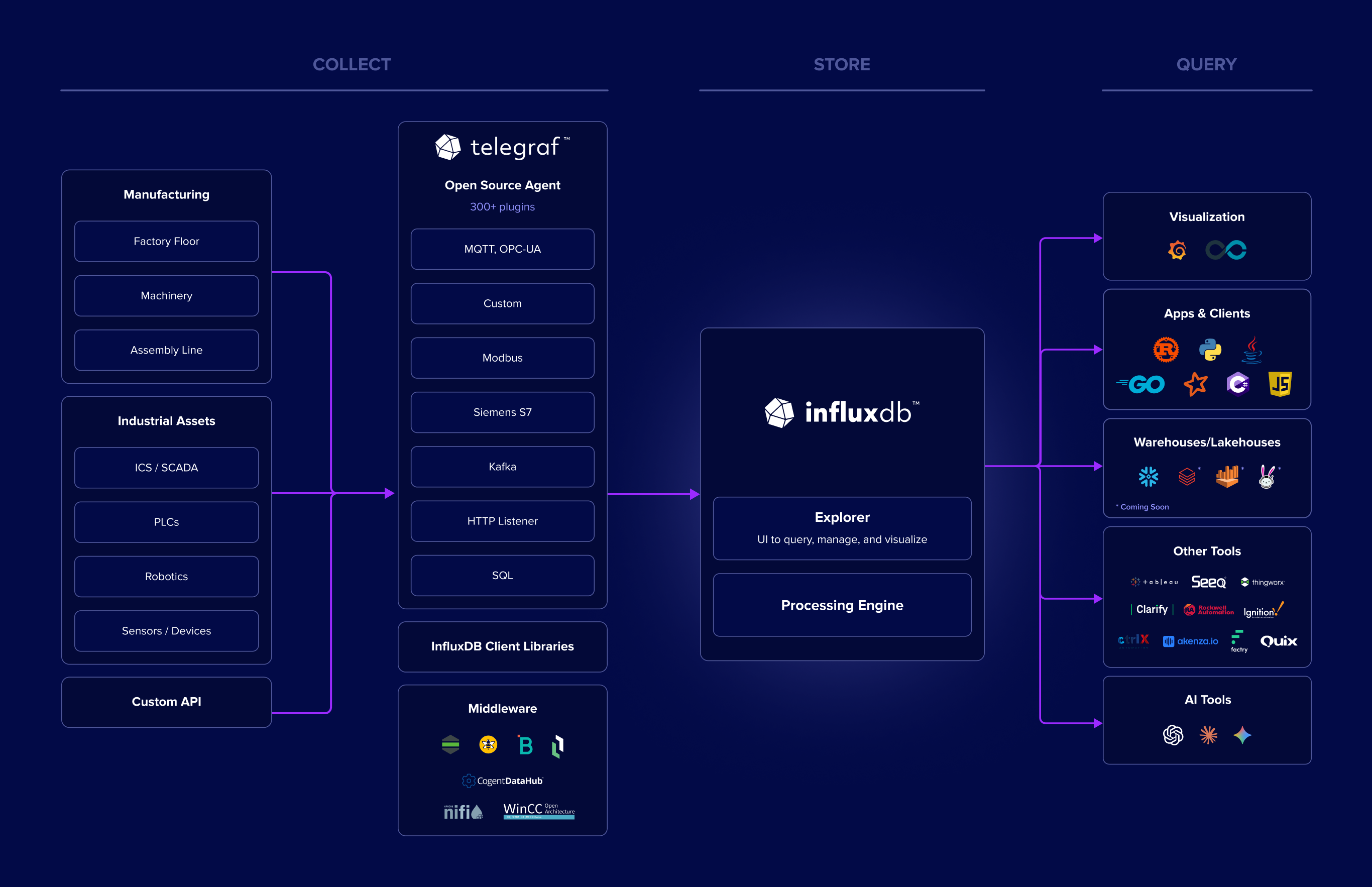

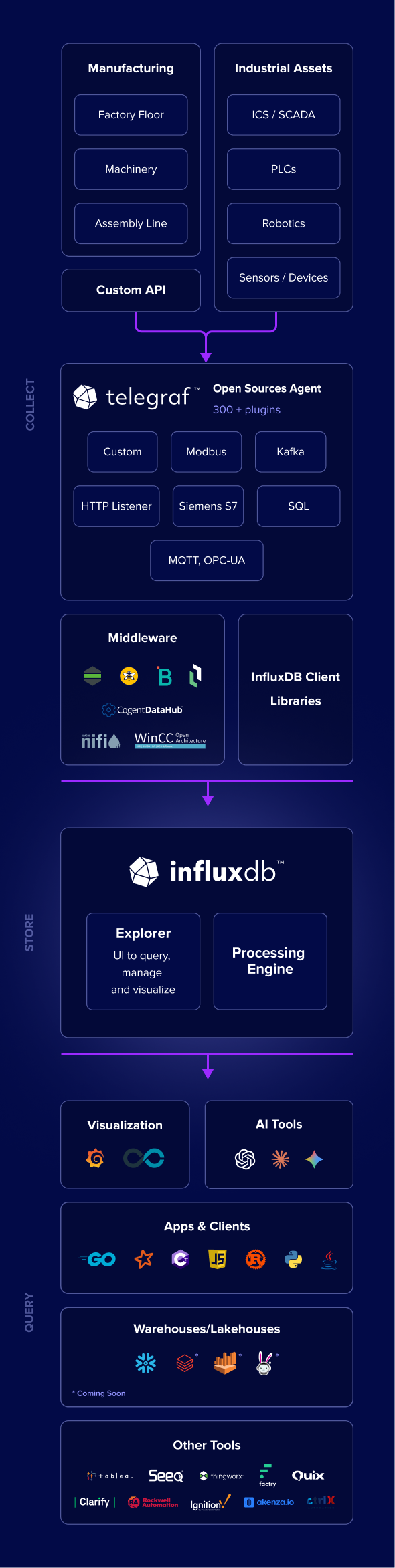

Open connectivity from edge to cloud

InfluxDB streams machine and sensor data across plants, production lines, and field assets using open protocols and 300+ Telegraf integrations. Connect PLCs, SCADA systems, and modern analytics tools without vendor lock-in, so operations, engineering, and IT teams can access high-frequency time series data anywhere it’s needed.

Deploy anywhere

Whether you're building on-prem, private cloud, edge, or multi-tenant cloud, InfluxDB meets developers where they are.

Additional resources

Time Series Buying Guide for IIoT

All machinery, equipment, and their controls and sensors tell a story through the data they collect. This data, known as Industrial Internet of Things (IIoT) data, provides a clear narrative about the machines and offers insights on how to improve operations.

Learn more

Industrial IoT for Energy | Live Demonstration

In this live technical demo, discover through real-life use cases how energy companies use InfluxDB in their production-ready environments to support predictive maintenance of critical infrastructure, optimize energy generation and distribution, and improve grid reliability.

Learn more

Getting Started with the MING Stack for IoT

Join us for an insightful webinar about the MING Stack, which includes MQTT, InfluxDB, Node-Red, and Grafana. This session will introduce participants to the essential components and collaborative dynamics of the MING Stack and demonstrate how it forms the backbone of IoT applications.

Learn moreTrial for Free

Start free with self-managed, our most popular setup.

Easily install for Linux, Mac, RHEL, Docker:

curl -O https://www.influxdata.com/d/install_influxdb3.sh && sh install_influxdb3.sh enterprise

For Windows installation, see the Getting Started Guide.

By default, trials are 30 days. Need more time? We can help extend it. Contact Us.